Bio Materials

| Item | Comment |

|---|---|

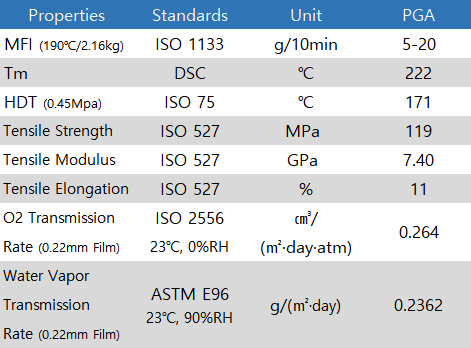

| PGA | Poly Glycolic Acid (PGA) is a biodegradable plastic that has excellent gas barrier properties and mechanical properties. In addition to materials for suturing, shale oil and gas extraction, its application is expanding to food packaging films that require barrier properties.

Advanced Materials & Chemicals Co., Ltd. is supplying PGA to the Korean market in collaboration with world-class suppliers. It has soil, ocean, and home biodegradation certification and is complete with food contact-related approval. ■ Key properties of PGA

|

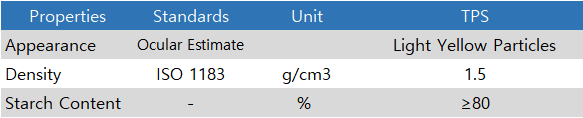

| TPS | Thermo Plastic Starch (TPS) is made from corn, potatoes, etc. and is a biodegradable plastic.

It has a competitive price and excellent biodegradability compared to other biodegradable plastics. It is compounded with PBAT and PLA according to the needs of users and is used in various applications.

Advanced Materials & Chemicals Co., Ltd. is supplying the excellent quality TPS at a competitive price.

■ Key properties of TPS

|

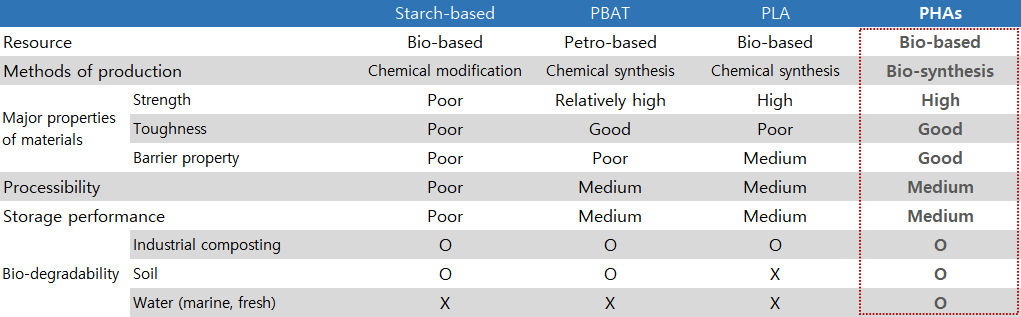

| PHAs | Polyhydroxy Alkanoate (PHA) is a bio-based biodegradable plastic made by microbial fermentation. It has excellent physical properties and biodegradability in soil, ocean, and home, providing a sustainable alternative to solving environmental pollution problems caused by existing non-degradable plastics.

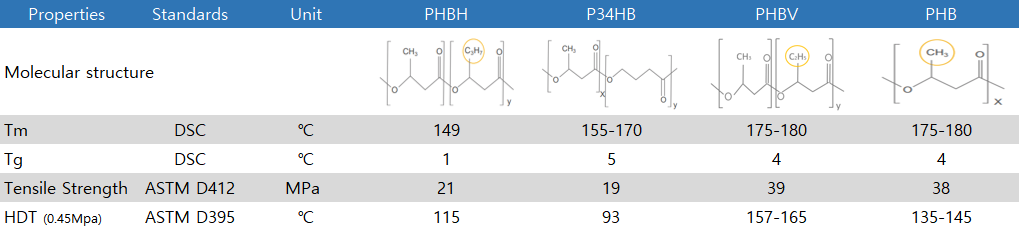

Advanced Materials & Chemicals Co., Ltd. is providing all kinds of PHA products such as PHBH, P34HB, PHBV, and PHB in collaboration with industry-leading PHA manufacturers.

■ Key properties of PHA by products

|

| PBS | Polybutylene succinate (PBS) is a biodegradable plastic that decomposes into water and carbon dioxide with the microorganism under the soil. PBS has excellent processability and high heat resistance among the general biodegradability resin. It is compounded with PBAT and PLA to meet the needs of users and is used in various applications such as injection, fiber, and film.

Advanced Materials & Chemicals Co., Ltd. is supplying selected high-quality PBS at a competitive price.

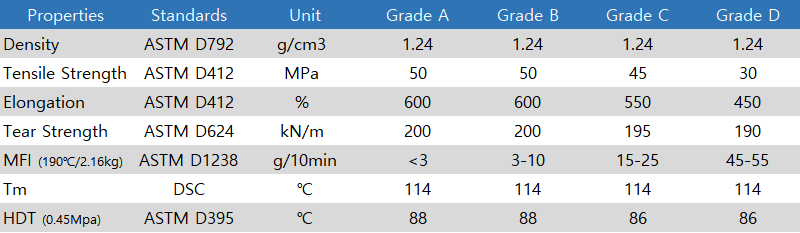

■ Key properties of PBS by product code

■ Tested and certified by recognized and independent test institutes

|

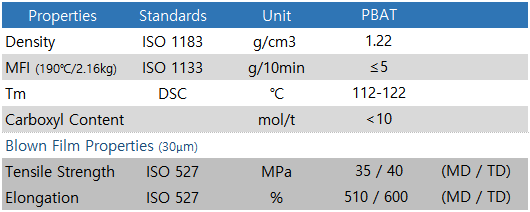

| PBAT | Poly butylene Adipate Terephthalate (PBAT) is a biodegradable, aliphatic-aromatic copolyester based on the monomers 1.4-butanediol, adipic acid and terephthalic acid in the polymer chain. It has excellent biodegradability, flexibility and processability.

various application such as disposable bags, shopping bags, and agricultural films.

at a competitive price.

■ Tested and certified by recognized and independent test institutes

|

| PLA | Poly Lactic Acid (PLA) is a biodegradable and compostable thermoplastic derived from renewable plant sources, such as starch and sugar. Its demand is increasing worldwide due to its wide range of applications and excellent competitiveness of price due to its similar physical properties to petroleum-based plastics. BBCA Biochemical is a joint venture between the BBCA, a Chinese biochemical and pharmaceutical conglomerate, and Futerro, an affiliate of Belgium's Galactic. It has a production capacity of 640,000 tons of Lactic Acid and 400,000 tons of PLA, and uses the world's best PLA production facilities, technology and know-how to supply PLA around the world for extrusion, injection, and textile industries.

BBCA's PLA is supplied to the Korean market through Advanced Materials & Chemicals, an official agency and an distribution channel.

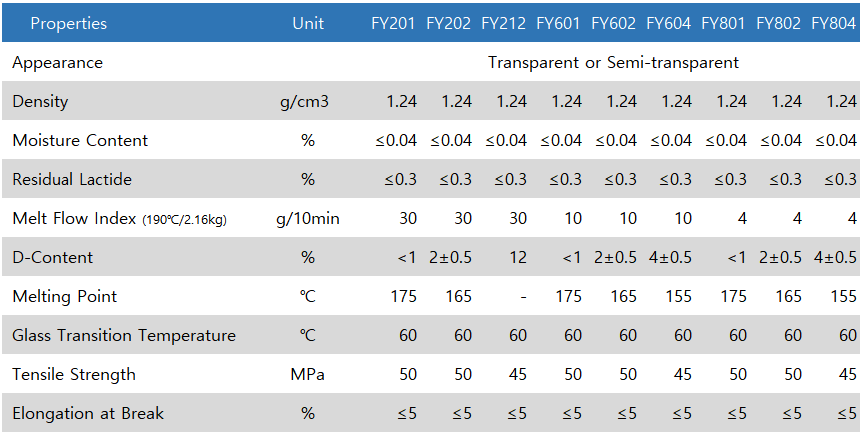

■ Key properties of BBCA's PLA by product code

■ Tested and certified by recognized and independent test institutes

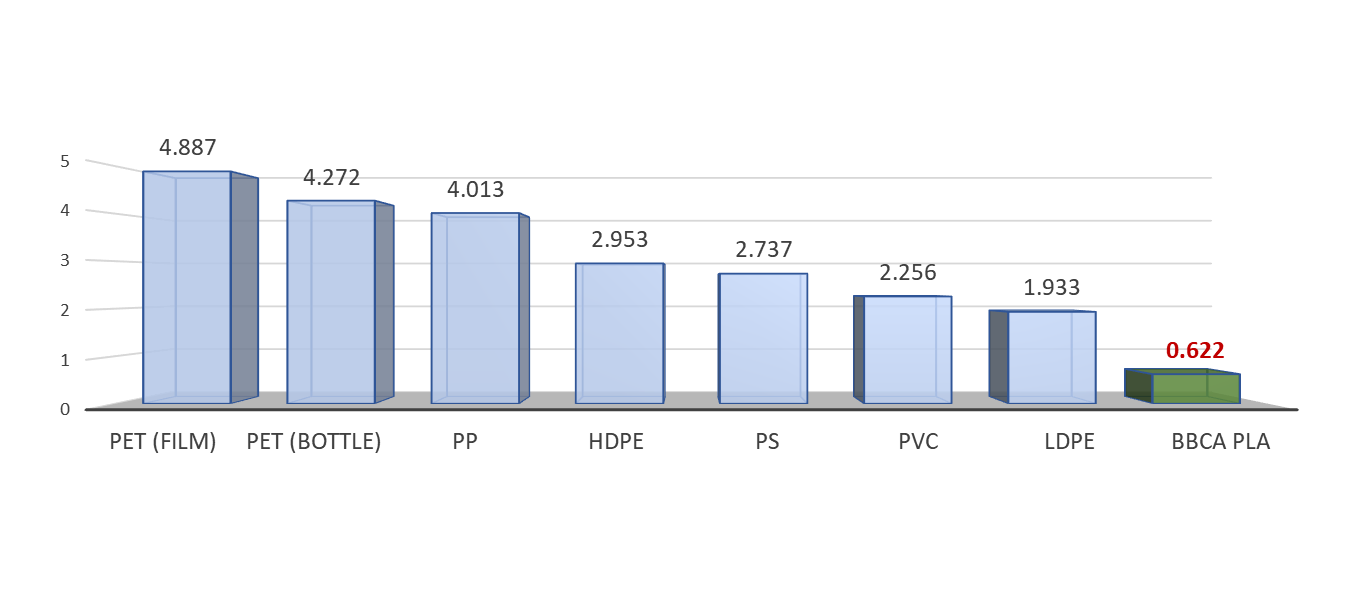

■ CO2 Emissions Comparison: Petroleum-based non-degradable plastics VS BBCA's PLA ▶ The measurement of CO2 emissions during the entire process of BBCA’s PLA 1kg production through the Life-Cycle Assessment (LCA) resulted in 0.622kg of CO2 that was reduced by up to 87% compared to petroleum-based non-degradable plastics.

|

EN

EN KR

KR

Privacy Policy

Privacy Policy