Advanced Equipment

| Item | Comment |

|---|---|

| 초임계 발포 압출 설비 | Super-critical CO2/N2 foaming facility is a stable and eco-friendly facility compared to conventional chemical and physical foaming methods using inert supercritical gases such as CO₂ and N₂. It is mainly produced in the form of sheets or beads and can respond to various fields such as insulation, cushioning packaging, disposable containers, EP (Engineering Plastics) or elastomer application industries.

Japan's PLASTECO supercritical foaming extruder is capable of maintaining precise and stable foaming with the world's top technology. It is also possible to form foam on materials that have not been realized due to chemical foaming. In particular, the quantitative supply control technology of inert gas, the most important technology in foaming molding, implements the best foaming results compared to other companies with PLASTECO's own technology.

Advanced Materials & Chemicals Co., Ltd. is a Korean distributor for PLASTECO's Super-critical CO2/N2 Foaming Facility.

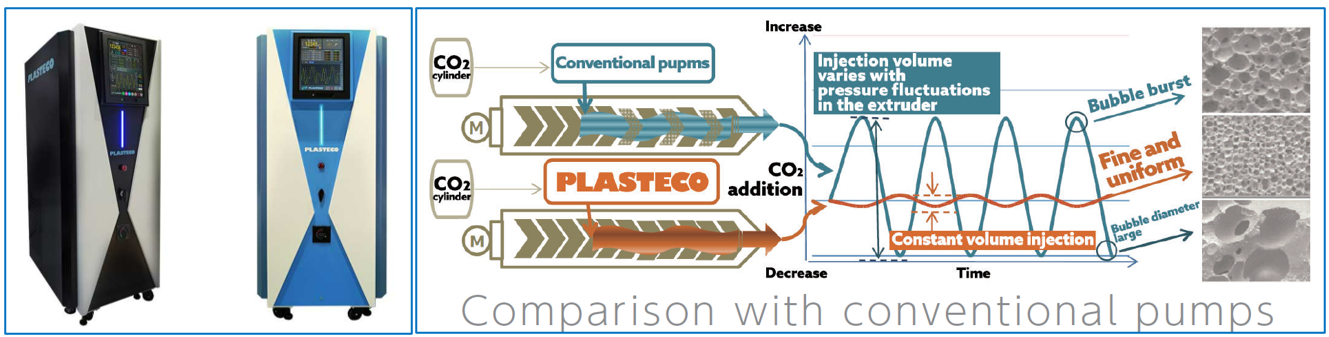

■ Special Features of PLASTECO facilities A typical pressure-controlled pump controls the amount of injection in response to pressure fluctuations in the extruder, but PLASTECO's gas-quantitative supply unit can maintain a uniform supply by constantly controlling the supply mass and automatically tracking the supply pressure to the pressure of the supply. (PLASTECO's proprietary technology) → Stable and uniform foaming is possible

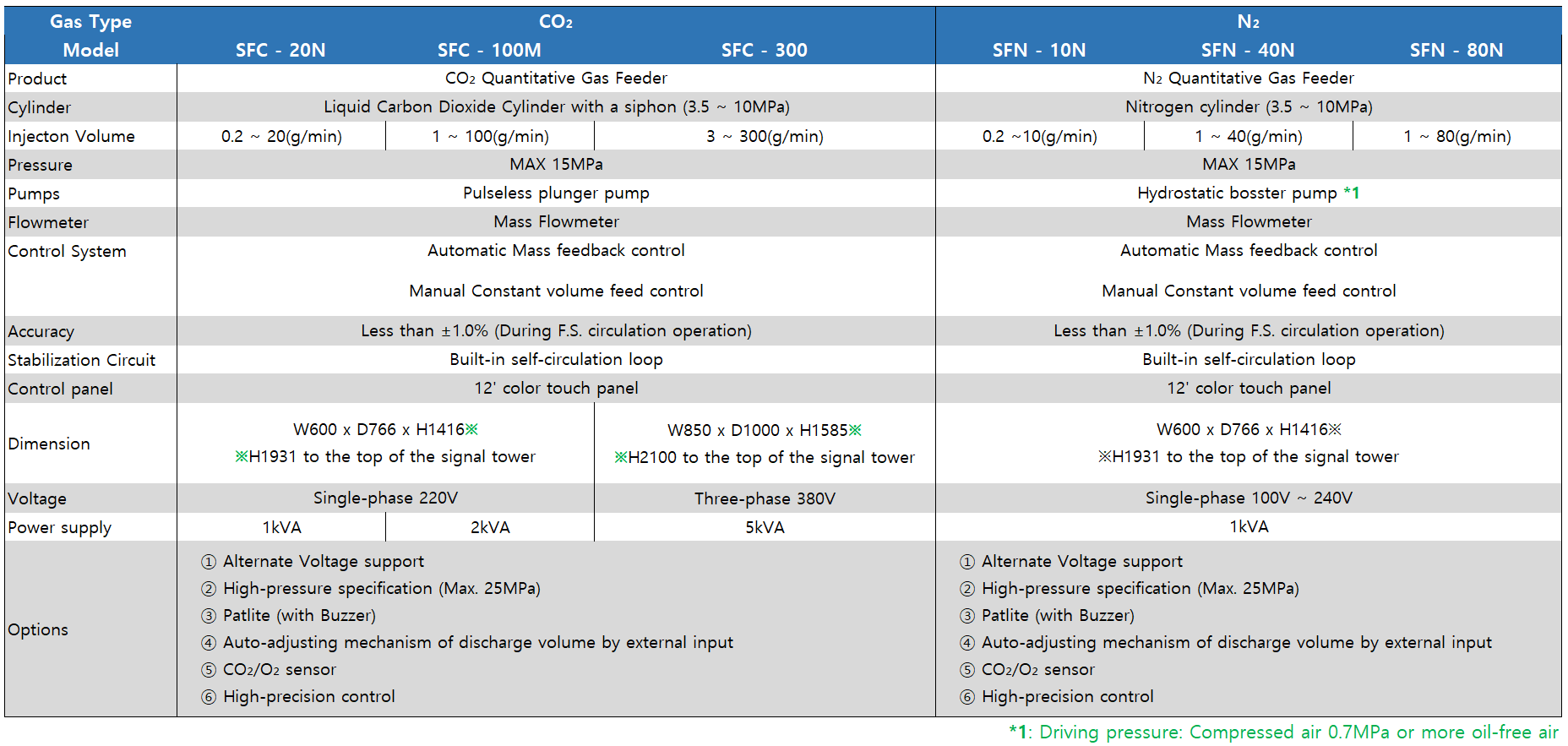

■ Specifications

|

EN

EN KR

KR

Privacy Policy

Privacy Policy