Polymers

| Item | Comment | ||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FKM | FKM is a high-performance rubber, especially with excellent resistance to high temperatures, ozone, weather, oxygen, mineral oil, fuel, hydraulic fluids, aromatic and many organic solvents and chemicals.

Application It is widely used for special parts materials such as gaskets, oil seals, fuel hoses and OA equipment, petrochemical plant pipes, semiconductor manufacturing, and gas sealing.

Physical property

|

||||||||||||||||||||||||||||||||||||||||||||||||

| PVDF | PVDF is a well-balanced engineering plastic that has the excellent properties of fluoride resin as well as moldability. Its applications are expanding in advanced technology fields such as electronic materials, binders for lithium-ion battery electrodes, and water treatment systems, including membranes, filters. Compared to other fluoropolymers, it exhibits superior secondary processing capabilities, including injection molding, extrusion, powder coating, and welding, without the need for additives such as plasticizers and thermal stabilizers during processing, resulting in high purity. Our company is currently selling products for water treatment systemsand electrical and electronic components, and we are expanding our market. |

||||||||||||||||||||||||||||||||||||||||||||||||

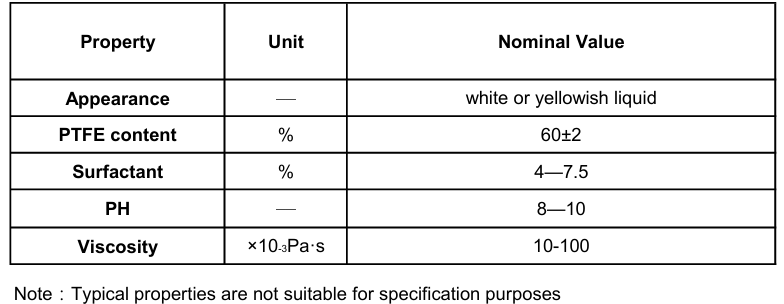

| PTFE | Polytetrafluoroethylene (PTFE) has excellent heat resistance, chemical resistance, weather resistance, electrical properties, non-adhesive properties, and lubrication properties. It is used as various component materials such as extrusion, injection, painting, adhesion, ink, coating, and semiconductor equipment. Product Characters Has good wetting performance, especially for impregnation of glass fiber. Has good dispersion performance, can mix with other Dispersion.

Application Impregnation of glass fiber and asbestos, high grade non-stick coating(PFOA free)

Packing, Storage & Transportation Not classified as hazardous for transport. During transportation and storage, avoid heavy shaking, high temperature and below 0℃. After three months, shaking the drum every week to avoid the deposition. Package : 25kgs and 1250kgs per drum

|

||||||||||||||||||||||||||||||||||||||||||||||||

| PPS | PPS is a super engineering thermoplastic. It is a high-performance polymer with a crystalline structure. PPS offers exceptional heat resistance, dimensional stability, chemical resistance, and electrical insulation. PPS is used in a variety of industries, including automotive, electrical, electronic, precision facilities. Properties is such as high temperature and chemical resistance, mechanical strength, dimensional stability, electrical insulation. (The load deflection temperature is above 260°C, the continuous use temperature is between 200°C and 240°C, and the melting point is 281°C.) |

||||||||||||||||||||||||||||||||||||||||||||||||

| MS | Microsphere is a closed cell foaming agent that is sometimes referred to as thermo expandable microcapsules. The hydrocarbon blowing agent resides inside an acrylic shell. When exposed to heat the shell softens while the pressure inside increases, allowing for rapid expansion. KUREHA has lineup of microsphere grades suitable for a wide range thermoplastics; including advanced grades that are compatible with higher temperature polymers. Microsphere is used in wide range of applications including ceiling materials, glass run channels, weather strips, shoe soles, foam ink, wallpaper, heat release tape, artificial leather, and 3D printers. This product is manufactured by KUREHA, and our company is the sales agent for this product in South Korea. |

||||||||||||||||||||||||||||||||||||||||||||||||

| PC | Polycarbonate(PC) resin polymerized using the double hydroxy compounds of bisphenol-A (BPA) and the carbonate compounds of diphenyl carbonate (DPC). It is widely used in various fields such as electronic products, automobiles, and mechanical components because it has characteristics such as impact resistance, heat resistance, and transparency. |

||||||||||||||||||||||||||||||||||||||||||||||||

| PPE | PPE plastic, often referred to as PPO™ plastic (polyphenylene oxide), is an amorphous thermoplastic with high heat resistance. It has excellent chemical resistance to water and most salt solutions, acids and bases. PPE polymer also has extremely low moisture absorption and is not affected by repeated exposure to water. It therefore offers good electrical insulation properties over a wide range of humidity and temperature, as well as good dimensional stability. PPE plastic material is rarely used in its pure form. It is mainly used as a PPE blend with other polymers such as PS, PBT, PA or PP. Currently, it is an imported product market without domestic manufacturing. AMC is the general distributor of Sinochem of China which is one of producer among the world's top three manufacturers, we have the largest supply of neat resin and the largest domestic market share for neat products. |

||||||||||||||||||||||||||||||||||||||||||||||||

| PBT | The plastic PBT is a semi crystalline thermoplastic belonging to the family of polyester polymers. PBT plastic is characterised by high strength, rigidity and dimensional stability when exposed to heat, as well as very high dimensional stability and a low tendency to creep. PBT material is also particularly suitable for food processing applications as it offers excellent resistance to chlorinated and corrosive cleaning solutions. Like all polyesters, PBT polymers have excellent friction and wear properties. However, compared to PET polyester, PBT plastic material offers better impact resistance - especially at low temperatures. Because of this property, PBT is much easier to modify with fibres than PET and is therefore usually available as a fibre-reinforced product. Currently, there is no domestic manufacturing facility in Korea. As the general distributor of Sinochem of China, AMC is continuously expanding the market with quality excellence, stability of supply through neat and compound product. |

||||||||||||||||||||||||||||||||||||||||||||||||

EN

EN KR

KR

Privacy Policy

Privacy Policy