Advanced Equipment

| Item | Comment |

|---|---|

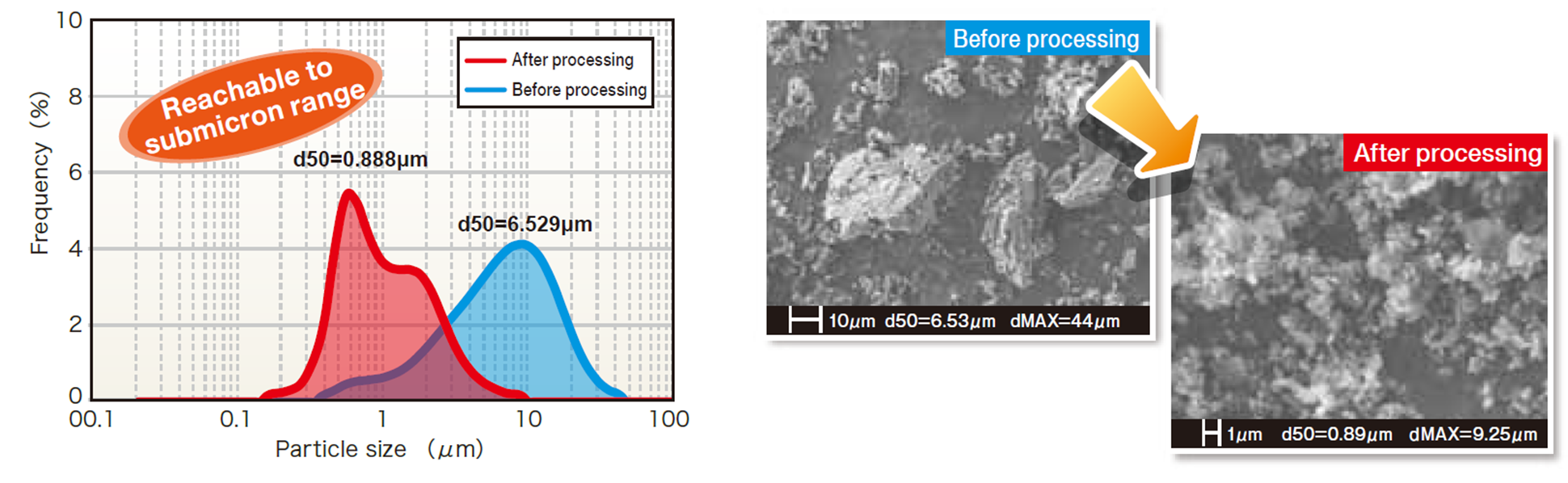

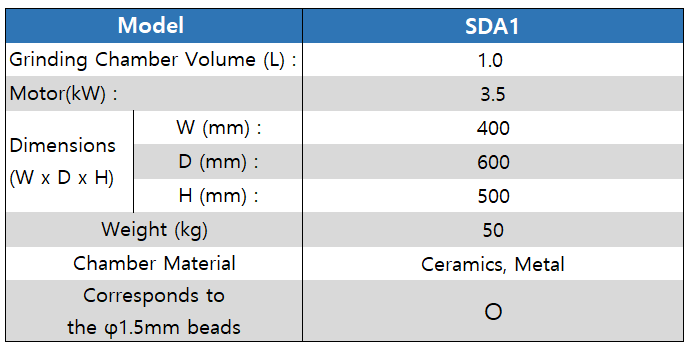

| Dry Star SDA1 | Dry Star SDA1 is the only tabletop continuous dry bead mill in the industry that can grind up to sub-micron (100x the capacity of a ball mill)

- It can be tested with only electric power and cooling water.

The products of Ashizawa Finetech, a Japanese manufacturer specializing in Beads Mill, are used in electronic materials, battery materials, ink, cosmetics, food, catalysts, and paper production processes of world-famous manufacturers for their high performance and high quality.

Ashizawa Fintech's bead mill is sold through its Korean agency, Advanced Materials & Chemicals. ■ Example (Activated Carbon)

■ Specifications

|

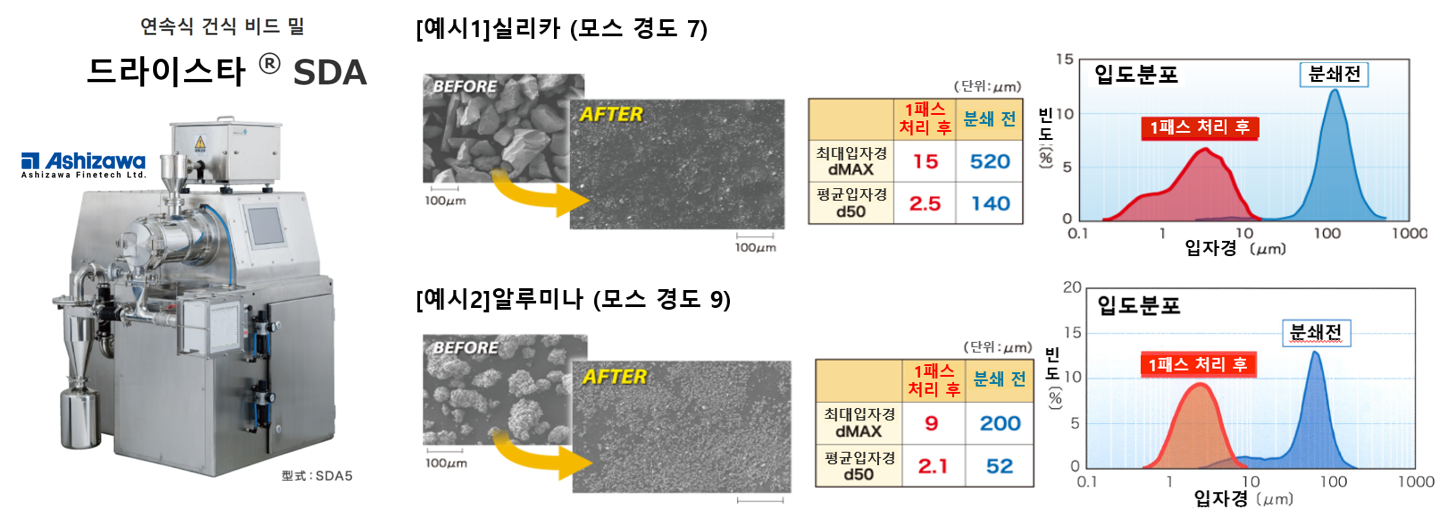

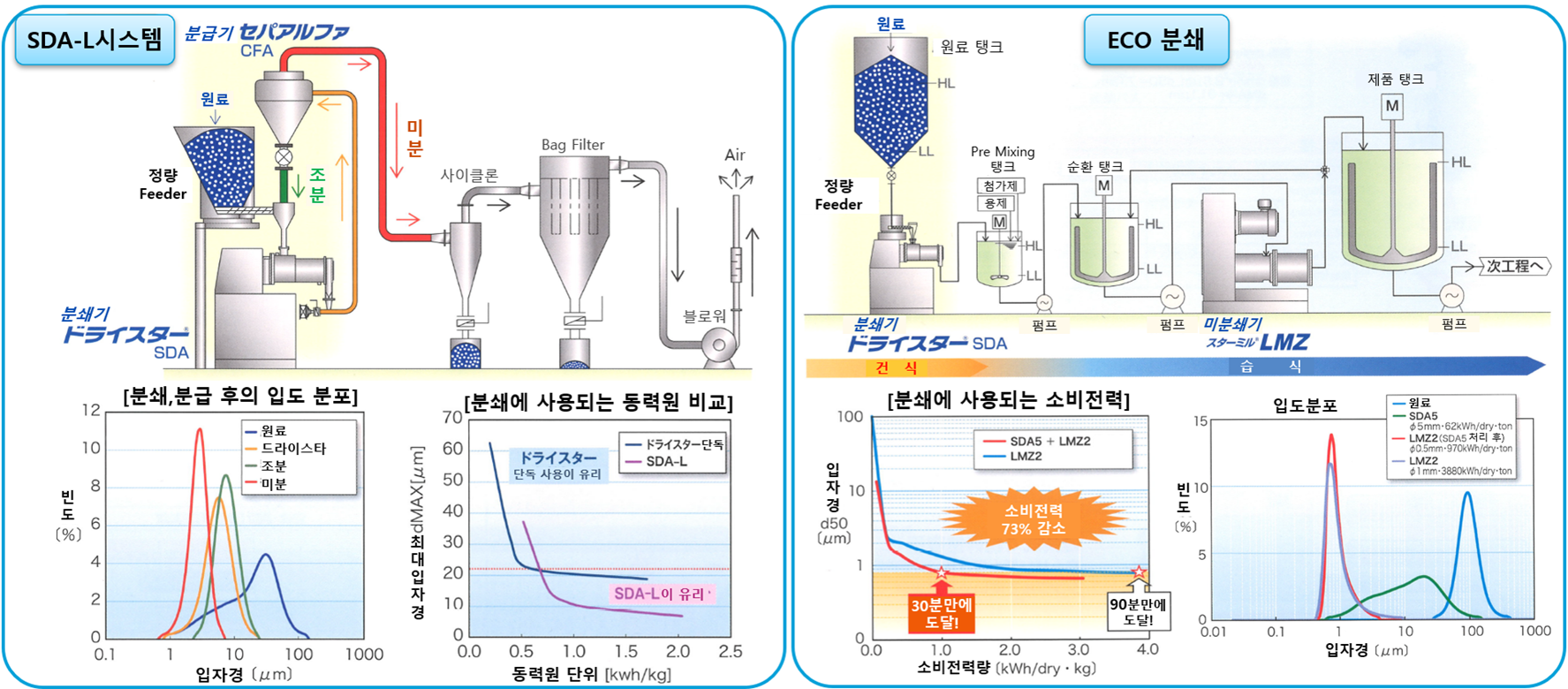

| Dry Star | Dry Star is a dry bead mill that can crush objects of about 100-150㎛ to single microns with one pass operation - Energy consumption cost is reduced to 1/10 (in the case of jet mill) compared to other methods of grinders (ball mill and jet mill).

to the use of only wet bead mill) in combination with wet bead mill, resulting in a more uniform particle size distribution and pollution suppression effect.

The products of Ashizawa Finetech, a Japanese manufacturer specializing in Beads Mill, are used in electronic materials, battery materials, ink, cosmetics, food, catalysts, and paper production processes of world-famous manufacturers for their high performance and high quality.

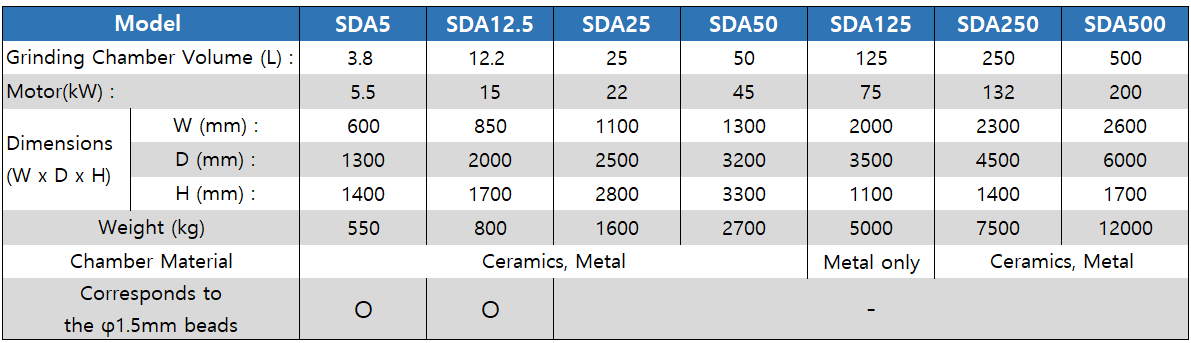

■ Specifications

|

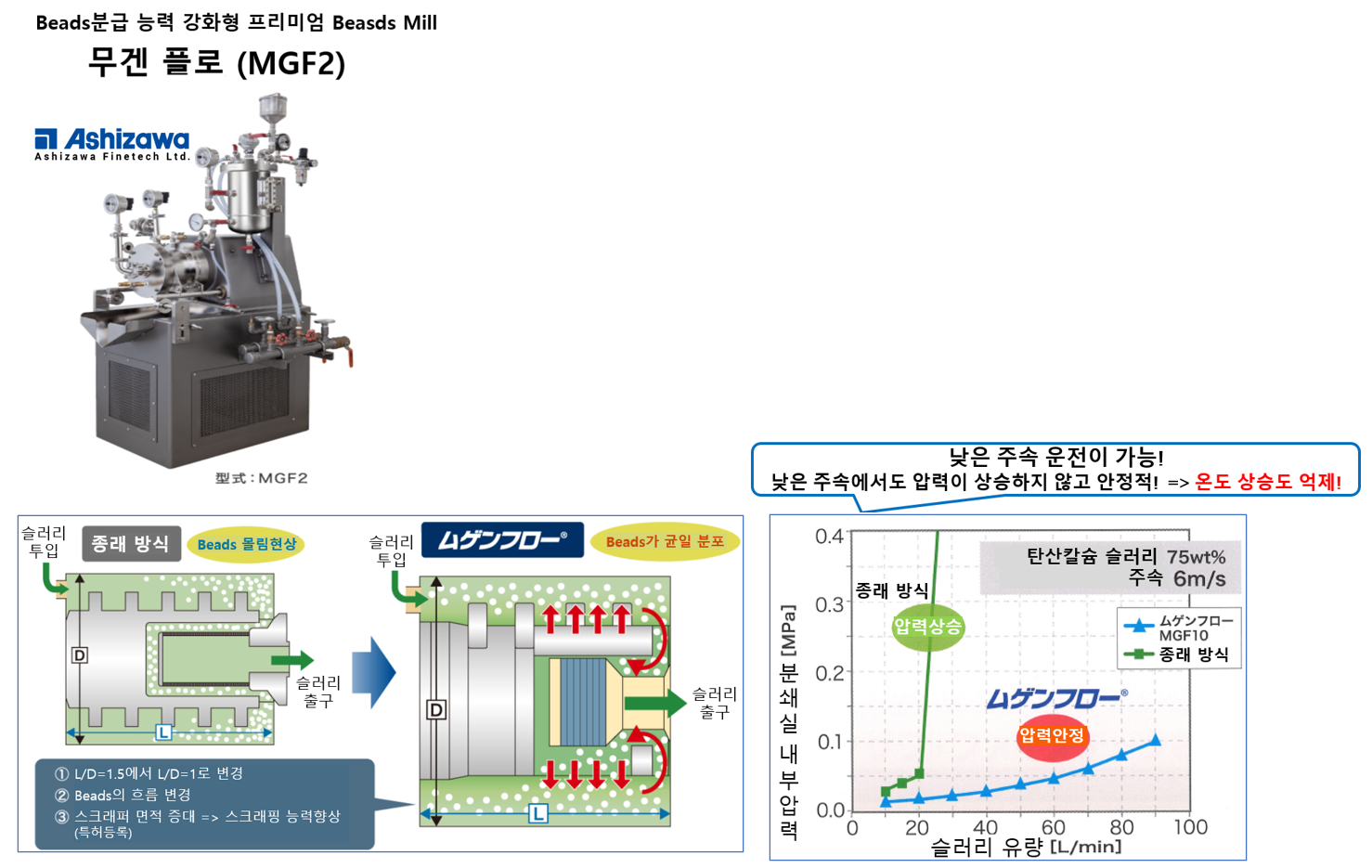

| Mugen Flow | Mugen Flow is a high-function bead mill that dramatically improves grinding capacity over conventional equipment.

as well as micronization to nano and submicron regions.

to treat objects that are easy to precipitate.

The products of Ashizawa Finetech, a Japanese manufacturer specializing in Beads Mill, are used in electronic materials, battery materials, ink, cosmetics, food, catalysts, and paper production processes of world-famous manufacturers for their high performance and high quality.

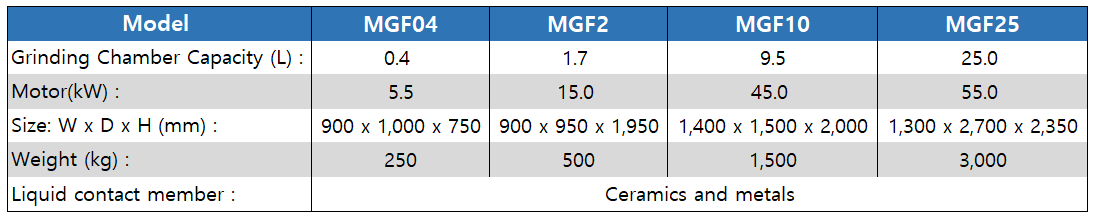

■ Specifications

|

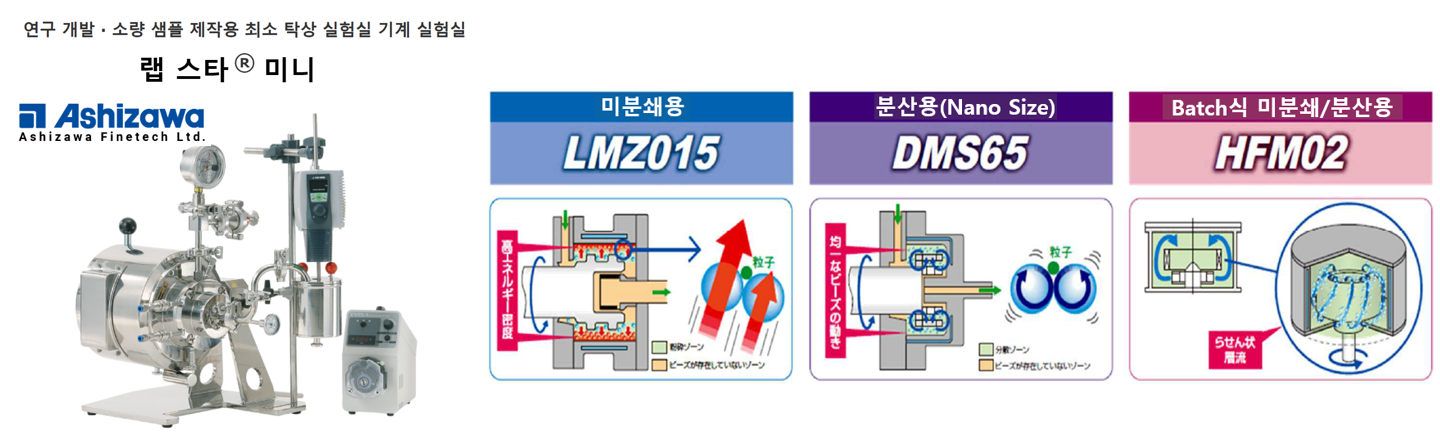

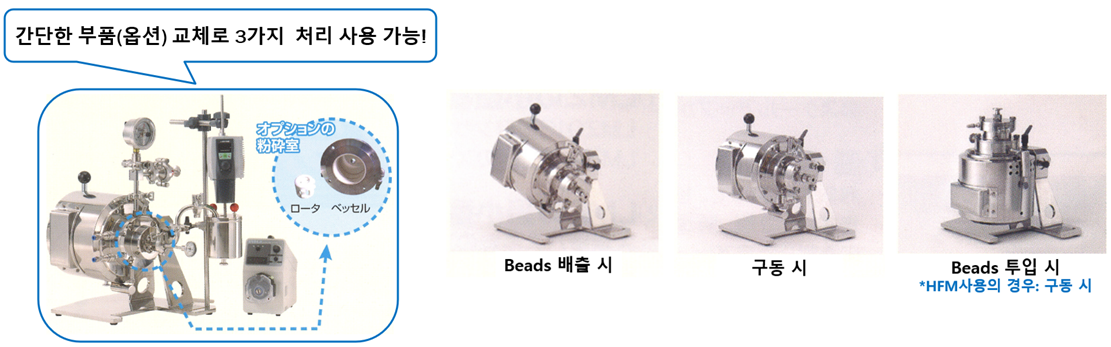

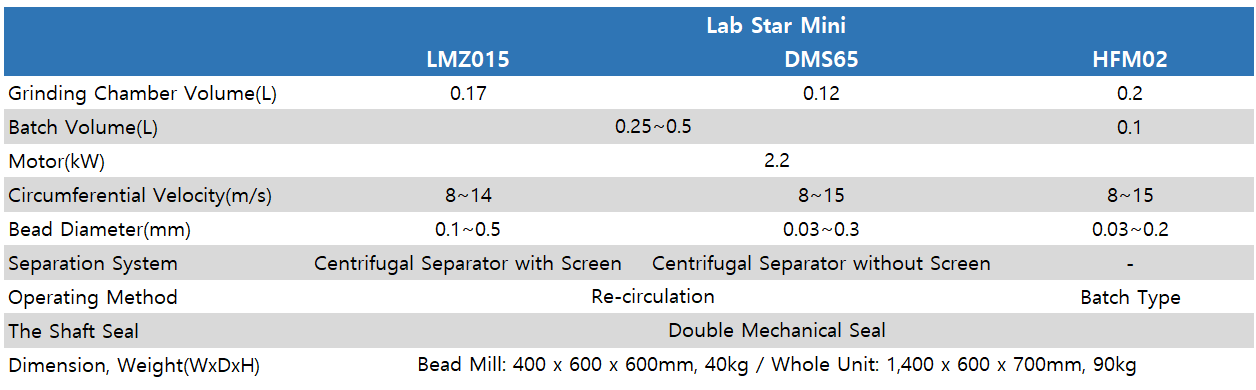

| Lab Star Mini | Lab Star Mini is a minimum-size bead mill suitable for research and development or small sample production.

▶ One common frame can respond to three types of processing

The products of Ashizawa Finetech, a Japanese manufacturer specializing in Beads Mill, are used in electronic materials, battery materials, ink, cosmetics, food, catalysts, and paper production processes of world-famous manufacturers for their high performance and high quality.

■ Specifications

|

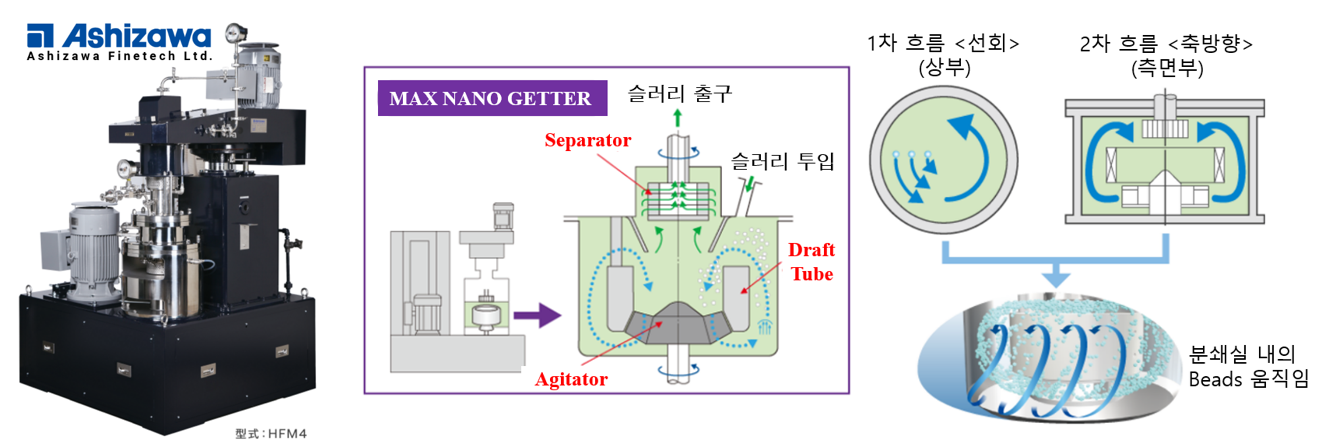

| Max Nano Getter | Max Nano Getter is a bead mill for mass processing of nanoparticle dispersion. It enables nano-scale grinding and dispersion. It is a model that applies the structure of a mixing and agitator to the bead mill, enabling mass processing of hundreds of kg/h, the industry's largest throughput.

The movement of the beads can be freely controlled according to the change in the type or viscosity of the object, so it can respond widely to various objects. A drive centrifuge is applied to ensure bead separation and stable use of microbeads.

The products of Ashizawa Finetech, a Japanese manufacturer specializing in Beads Mill, are used in electronic materials, battery materials, ink, cosmetics, food, catalysts, and paper production processes of world-famous manufacturers for their high performance and high quality.

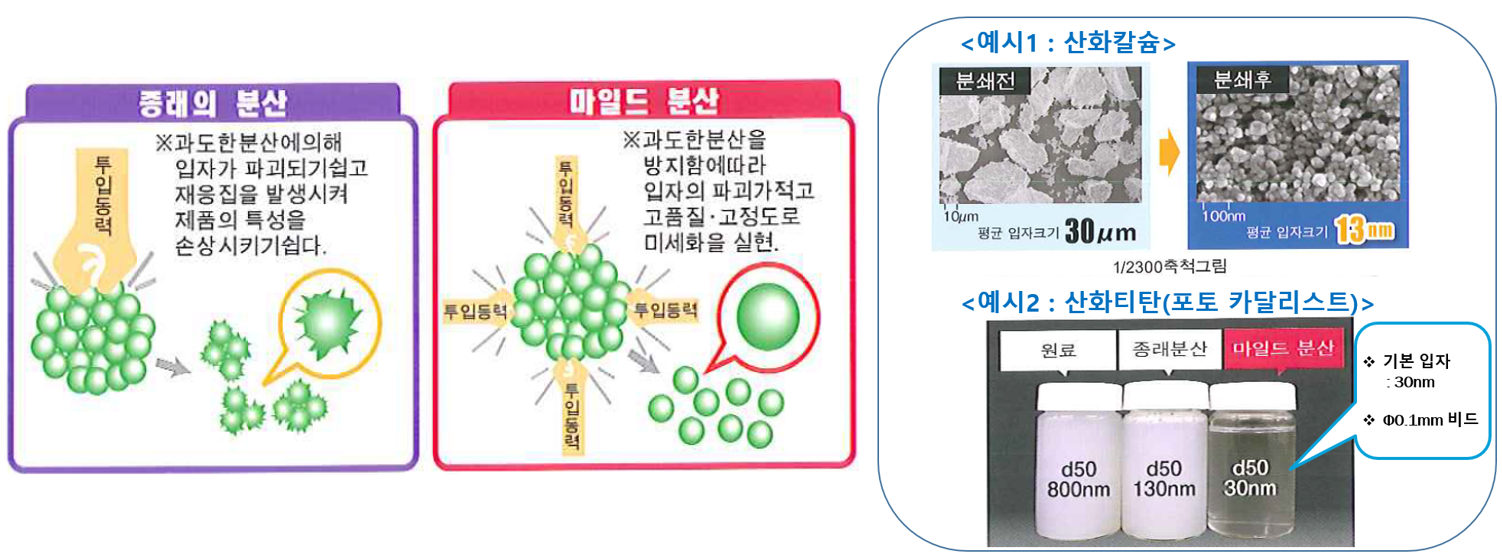

■ Proprietary technology of ASHIZAWA FINETECH bead mill This model is applied with Ashizawa Finetech's self-developed "mild dispersion" technology. It enables dispersion while maintaining the original size, shape, structure, and surface condition, and suppresses re-aggregation by minimizing particle damage and surface activation.

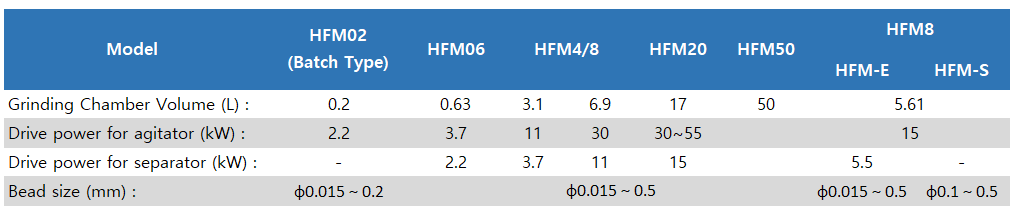

■ Specifications

|

EN

EN KR

KR

Privacy Policy

Privacy Policy