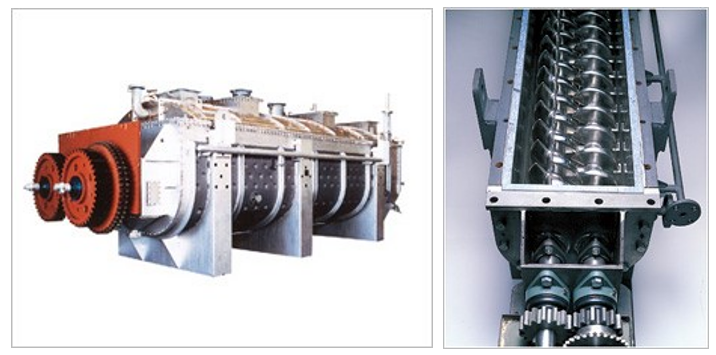

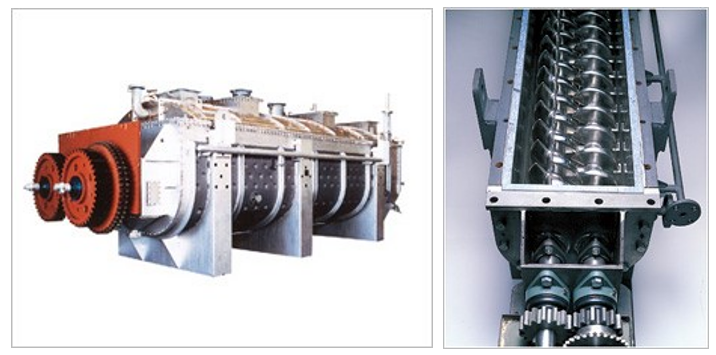

The paddle dryer (NPD) at Nara Machinery in Japan is used for various materials such as resins, sludge, food, and chemicals.

- Its biggest feature is its own heat transfer wing, developed by Nara Machinery. It is a representative model of a paddle-type stirring dryer for decades, offering its outstanding performance to the world.

- Not only can it cope with a wide range of particle size and shape materials such as particulates, pallets, and flakes,

but it can also be used in high-water content materials, slurry, and high-viscosity materials.

■ Special features

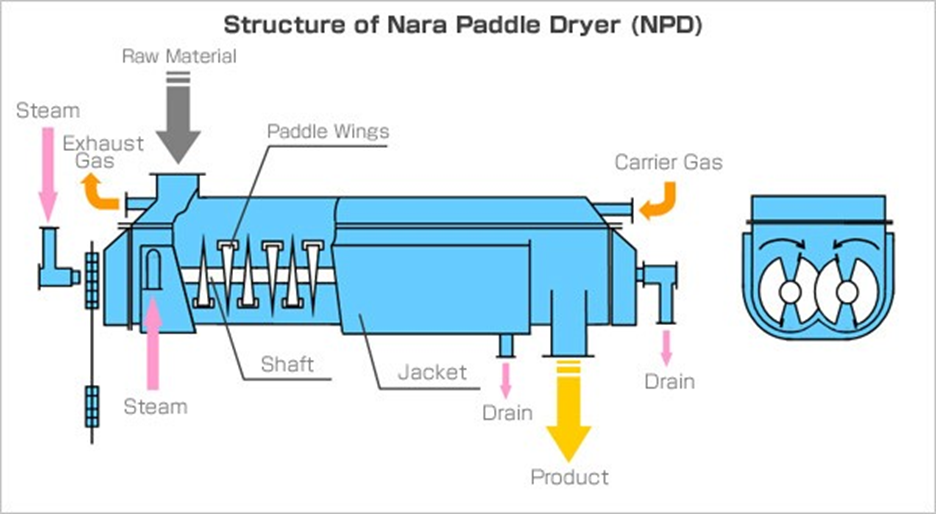

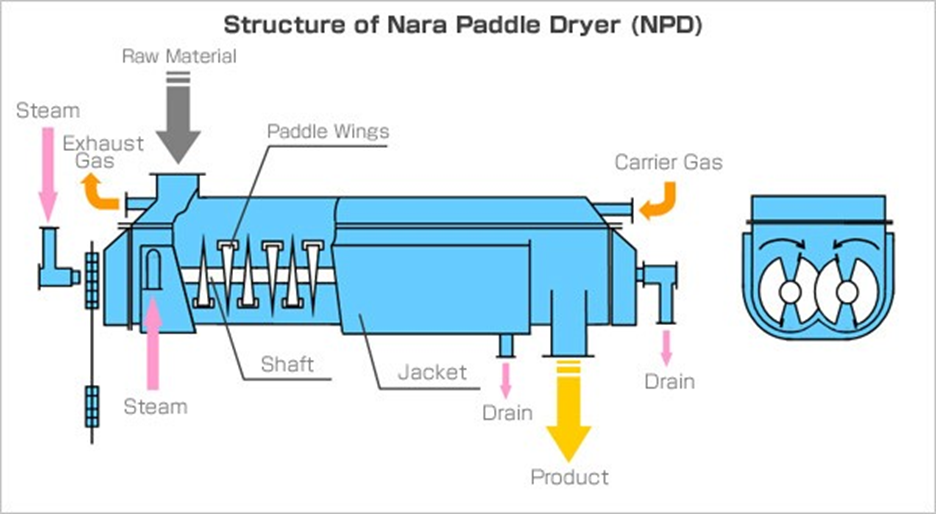

- It has a compact size because of its large heat transfer area per unit volume.

- It can achieve a large heat transfer coefficient by facilitating contact with the heat transfer plane by the effect of

wedge-shaped wings penetrating into the powder, and increasing the confusion of the powder. In addition, it has a high charging rate of 85-90%, so the heat transfer area can be effectively used.

- It prevents and inhibits adhesion by mutual motion of overlapping two-axis wedge-shaped wings. Therefore, effective heat transfer is always maintained.

- It has a narrow residence time distribution and no dry stains.

- It can be operated with low carrier gas emissions, so facilities such as dust collectors can be made small. Also, the solvent recovery used in the inert gas closing circuit can be a particularly big advantage.

- It can also treat mud-like materials or adhesives with high moisture content.

- Since it can be operated under reduced pressure, continuous drying of materials weak to high temperatures is possible using a boiling point drop.

- It can be treated at high temperatures (~290℃) by using oil as a heat medium.

- It is possible to design a device that dries and cools at the same time.

|

EN

EN KR

KR

Privacy Policy

Privacy Policy